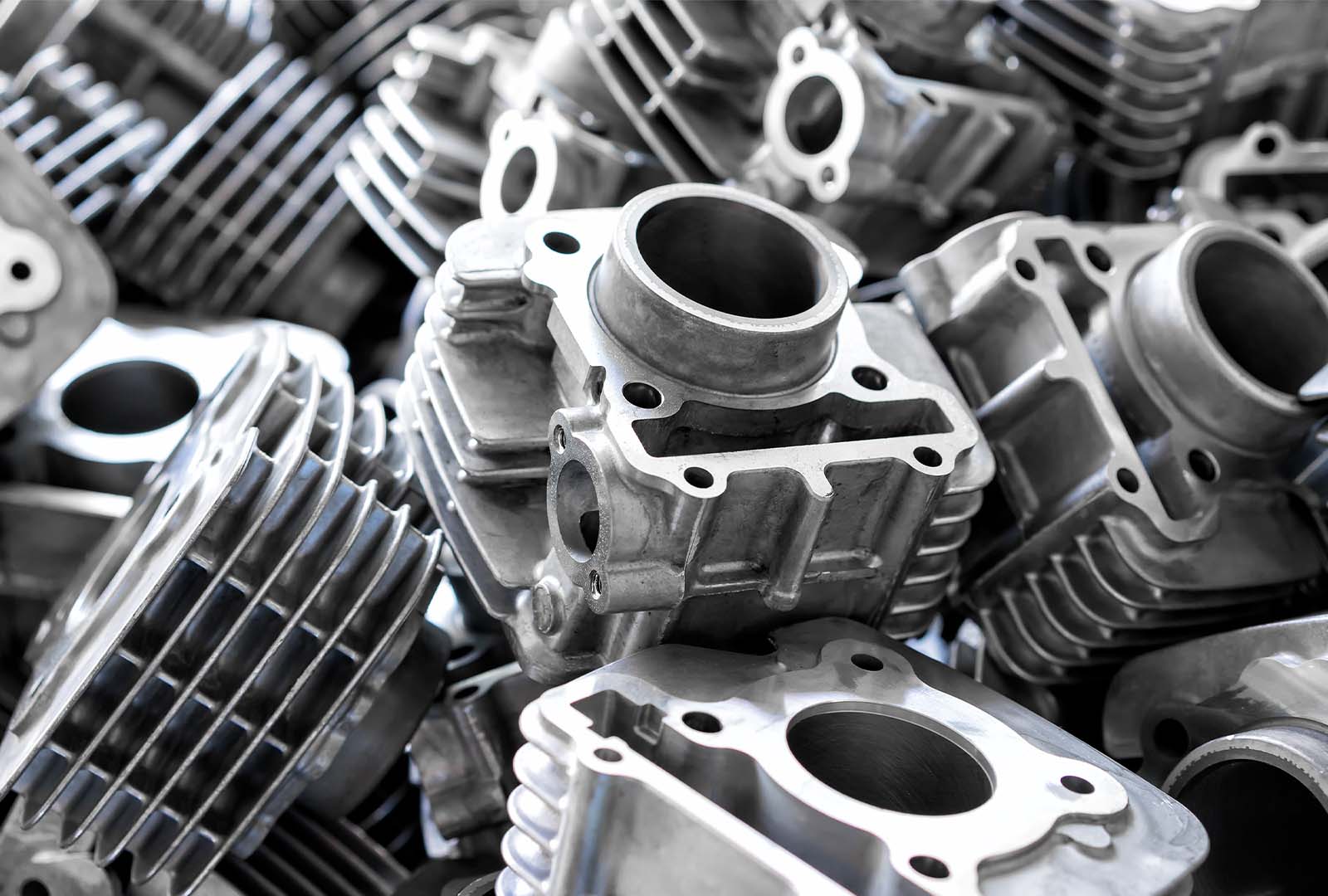

Diecasting is a process of manufacturing which has become essential to the manufacturing of metal parts with high precision as well as Malaysia is now a major participant in the industry. This process is the act of forcing the molten metal with high pressure into a mold, and then cooling it rapidly into a solid piece. The process is renowned for its intricate shapes that have outstanding surface quality and precision. In Malaysia the industry of diecasting has experienced significant growth due to technological advancements and a highly skilled workforce as well as a favorable business climate. The article focuses on the growth in the current situation, as well as potential future developments of diecasting Malaysia.

Diecasting’s origins in the manufacturing industry of Malaysia is traceable to the middle of the 20th century as the nation began industrializing and diversifying its economic base. At first, the business predominantly focused on making simple components that could be used for domestic purposes, however in the past, it is now expanding and evolving. In the present, Malaysian diecasters produce a diverse range of items that include automotive components electronic housings, electronic components, as well as consumer products. The transformation was aided with the help of modern machines and the use of cutting-edge methods and an emphasis on controlling quality. Growth in the sector is assisted by efforts of the government to encourage export and manufacturing policies.

Technology advancements have been a major factor in the growth of the diecasting business in Malaysia. Modern machines for diecasting are fitted with advanced control systems to assure consistent, precise production. Innovative technologies like computer-aided design (CAD) or computer-aided manufacture (CAM) have changed the process by which diecast pieces are created and manufactured. This technology allows for the development of extremely intricate and precise parts that reduce waste and increase effectiveness. In addition, the use advanced materials like magnesium alloys and aluminum, enhances the efficiency and endurance of diecast items. The advancements in technology have helped to position Malaysia as a leading market player on the international diecasting industry.

Diecasting’s success in the business in Malaysia can also be attributed to the skilled workers. Malaysian employees are renowned for their technical skills and dedication to quality that are crucial for a highly precise industry such as diecasting. Regional educational institutions as well as education programs have been crucial in establishing a pool of talent which can meet the demands of the industry. Regular professional training and on-the-job education ensures that employees stay current with new methods and techniques. A focus on the development of skills has allowed Malaysian diecasters to keep their high production standards and be competitive globally.

The future of high pressure diecasting malaysia looks positive. The demand in the world for diecast products is predicted to increase thanks to the automotive electronic, consumer electronics and goods industries. Malaysia’s strategically located, strong infrastructure and business climate make Malaysia an ideal location to invest in diecasting. Additionally, the business will likely gain from efforts ongoing to adopt sustainability and innovation. Environmental initiatives that reduce the impact like adopting more energy efficient methods and recycling of materials are growing in popularity. Through continuing investment in new technologies, expertise and environmentally sustainable practices Malaysia’s industry of diecasting is in a good position to sustain its growth and achieve achievement.

Diecasting in Malaysia is a long distance from its humble start to become a crucial element of the nation’s manufacturing industry. Diecasting’s growth is characterized by the advancement of technology and a highly skilled workforce as well as a favorable business climate. The demand for precise metal parts increases, Malaysia is poised to profit from this growth. In embracing the latest technology and sustainable practices in the diecasting industry, the Malaysian diecasting industry will be able to maintain its position as a leader and greatly contribute to Malaysia’s growth. Diecasting’s future in Malaysia is promising, and offers plenty of opportunities to expand and growth.